Surveying, Determination of rotary kiln geometric elements and mechanical adjustment

Surveying and determining the geometric elements of rotary kiln shall be exercised:

- Periodically, considering that wear of rings and carrier rollers resulting to disturbance of their projected geometric relationships,

- In the case of replacement or machining of rings or carrier rollers or

- On emergency conditions when problems arise in the work of rotary kiln.

This determination may be carried out:

- During operation by rotary kiln (hot condition) or

- As part of the overhaul of rotary kiln (cold condition).

Surveying for the purpose of determining the geometric elements of the rotary kiln include:

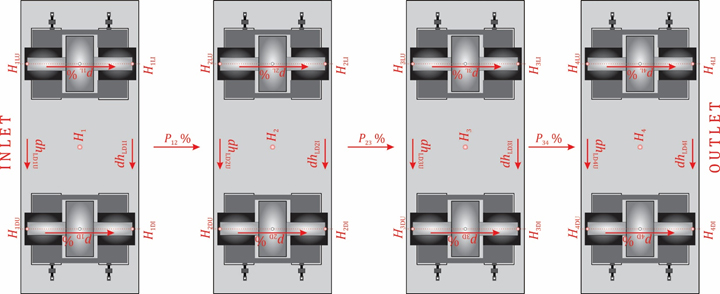

- Levelling the supporting plates on the supporting stations of the rotary kiln,

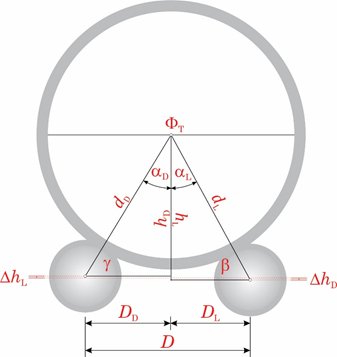

- Measurements of diameters of rings and carrier rollers and

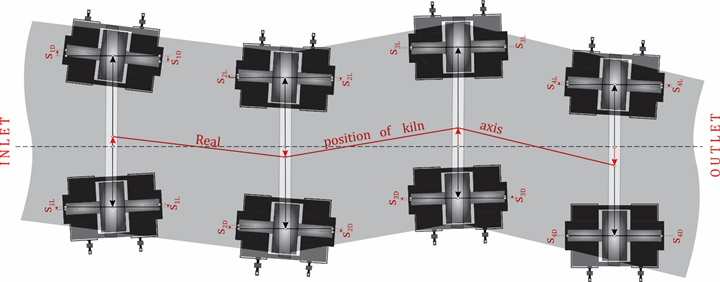

- Horizontal positioning of the carrier rollers in relation to the center of rings ie rotary axis of the rotary kiln.

Leveling the supporting plates on the supporting stations involves precise determination of vertical inclinations the supporting plate and inclinations between central points in the supporting stations.

Horizontal positioning of the carrier rollers:

- Determining the relative positions of the centers of carrier rollers and rings and peak angles of the ring to the left and right roll.

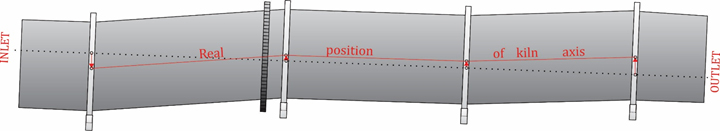

- Determination of spatial (horizontal and vertical) position of the axis of the rotary kiln as well as checking of parallelism rotary axes of carrier rollers to idealized (adjusted) axis.

Correction of geometric elements of rotary kiln (mechanical adjustment) aims to:

- Correcting the tilting of rotary kiln axis (if it has more than two supporting stations)

- Correction of vertical inclination of the rotary axis,

- Correction of supporting rollers skewings.