Surveying and Determination of rotary mill geometric elements

Surveying and determining the geometric elements of rotary mill shall be exercised:

- Periodically, considering that vibrations during operation of the mill may cause deformations and disturbance of the projected geometric relationships between the axis of the mill and the axis of the drive shafts,

- In the case of replacing the drive gears, tooth flange, parts of drive shafts or bearings on the drive shafts or

- On emergency conditions when problems arise in the operation of the rotary mill.

This determinations may be carried out:

- During operation by rotary mill (hot condition) or

- As part of the overhaul of rotary mill (cold condition).

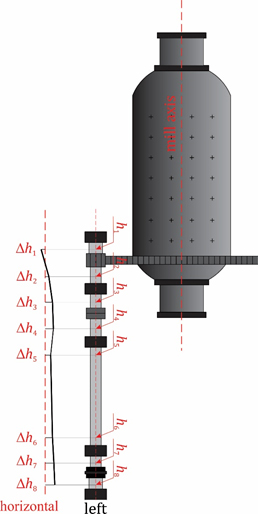

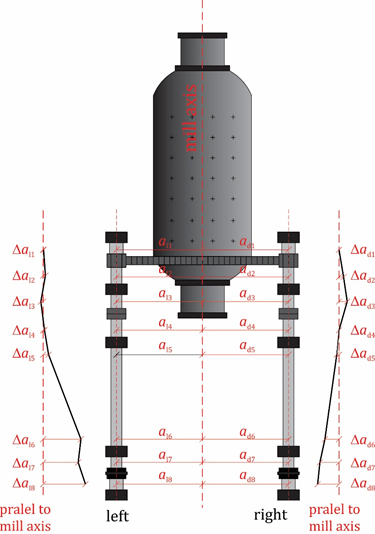

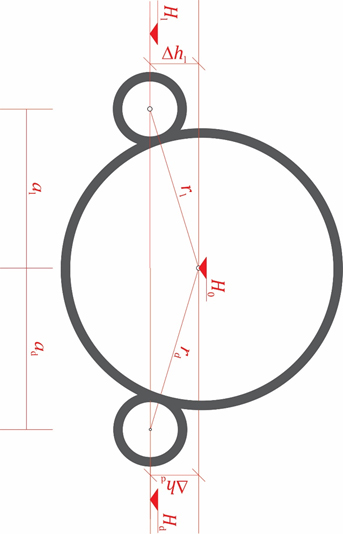

Surveying for the purpose of determining the geometric elements of rotary mills include:

- Levelling characteristic points on the drive shaft that is the ends of the drive shaft parts, relying mill characteristic points and characteristic points in the mill drive (electric motors and gearboxes),